ULTRA REFLEX GMBH, GERMANY

Precise solutions made of plastic

Reflectors and reflex reflectors, lenses and light guides, optical and technical plastic part, reflective tapes

Passion

competence

safety

Precise solutions made of plastic. Reflectors and reflex reflectors, lenses and light guides, optical and technical plastic parts, reflective tapes.

Plastic is our passion, our excellent manufacturing and processing quality as well as our excellent customer service are our recognition value. On this basis, we have earned the esteem as a competent and reliable partner in many industrial sectors.

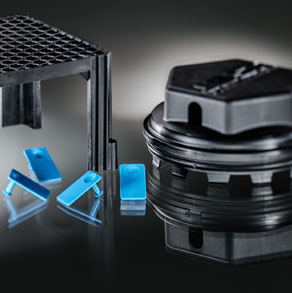

Whether in sensor technology, vehicle equipment or road equipment, Ultra Reflex impresses with its creative and precisely fitting products and components made of plastic. We develop, design, build tools, manufacture, process, assemble, package, store and deliver – the entire value-added process from one source, in one place.

Sustainability is a fundamental pillar of our entrepreneurial activities. With the selection of our production machines, we ensure resource-saving and energy-efficient plastic processing. As a family business, we are a reliable employer for our employees.

PRODUCTS

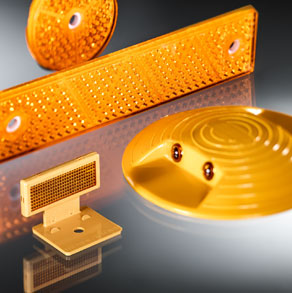

Reflectors for photoelectric sensors

Automotive Lighting

Traffic safety equipment

Reflective tapes

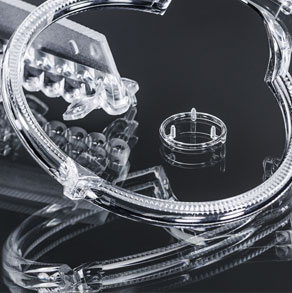

Optical plastic parts

Transparent design parts

Technical plastic parts

Reflex electroforms, tool inserts

Services

Consulting and project management

We know what matters – We share our knowledge and experience; project management based on the APQP process, FMEA and control plans to ensure product and process quality.

Development and construction

We love the challenge, technology and design and understand optics – We provide inspiration, create CAD drawings, do filling studies and produce prototypes.

Quality, cost awareness, delivery reliability

We document our quality with a modern CAQ system, we use high-precision measuring equipment and testing devices for our reflectors and optical plastic parts and we deliver on time. We set standards in terms of reliability.

Injection moulding production

We digitise, automate and monitor our injection moulding parameters and the entire injection moulding process. We process different thermoplastic materials. With 2-component injection moulding and injection compression moulding, we set standards in terms of precision.

Mould making

We manufacture mould inserts, complete injection moulds or even sophisticated 2-component injection and injection-compression moulds. We repair and maintain. We manufacture optical tool inserts with our own ultra-precise diamond milling machine. We set standards in terms of durability.

Assembly and ultrasonic welding

We make it complete – we are familiar with gluing, clipping, screwing, overmoulding inserts and ultrasonic welding. We set the standard for good connections.

Packaging

We label and package according to your individual wishes and requirements. Marking by means of engraving in the tool, screen or pad printing or by means of a glued-on product label as well as individual packaging in PE bags ensure the recognition value of your product.

Discover ULTRA REFLEX

Quality & Environmental

Sustainability

Jobs & Career

Corporate culture & values